Una planta de energía de un hospital en Alberta, Canadá, sufrió una falla en la tubería de agua por ósmosis inversa que provocó que el agua de la ciudad entrara directamente a sus calderas. Esta excursión de dureza provocó una gran acumulación de incrustaciones en las superficies de transferencia de calor de la caldera, y una de las calderas sufrió la ruptura de un tubo.

Inicialmente, Veolia recomendó un aumento temporal de la dosis del tratamiento existente, Solus AP26, que forma parte de la última tecnología de tratamiento interno y control de incrustaciones de calderas de Veolia. El producto Solus AP es un producto químico avanzado para el control de depósitos diseñado para garantizar superficies de transferencia de calor limpias, incluso en condiciones de tensión como trastornos por dureza del agua de alimentación.

Solus AP26 contiene cáustico, y la dosis más alta causó un aumento de los niveles de alcalinidad. Debido a la preocupación por el ataque de sustancias cáusticas en las calderas, Veolia buscó un tratamiento mejorado.

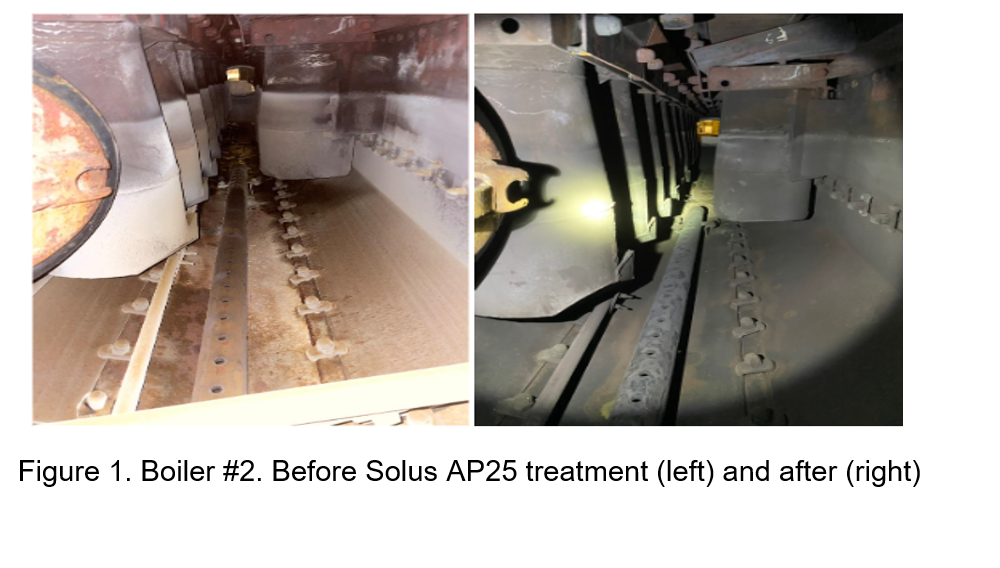

Se sugirió cambiar a Solus AP25 ya que tiene una mayor concentración de polímero y una menor contribución cáustica. El objetivo era seguir mejorando la eficiencia de la transferencia de calor de la caldera eliminando los depósitos de dureza y evitando la limpieza con ácido abrasivo en las superficies internas de la caldera con incrustaciones. Después de este cambio de programa, las imágenes de inspección de la caldera mostraron una eliminación significativa de depósitos de los tambores de vapor y los tubos de la caldera (Figura 1).

Resultado

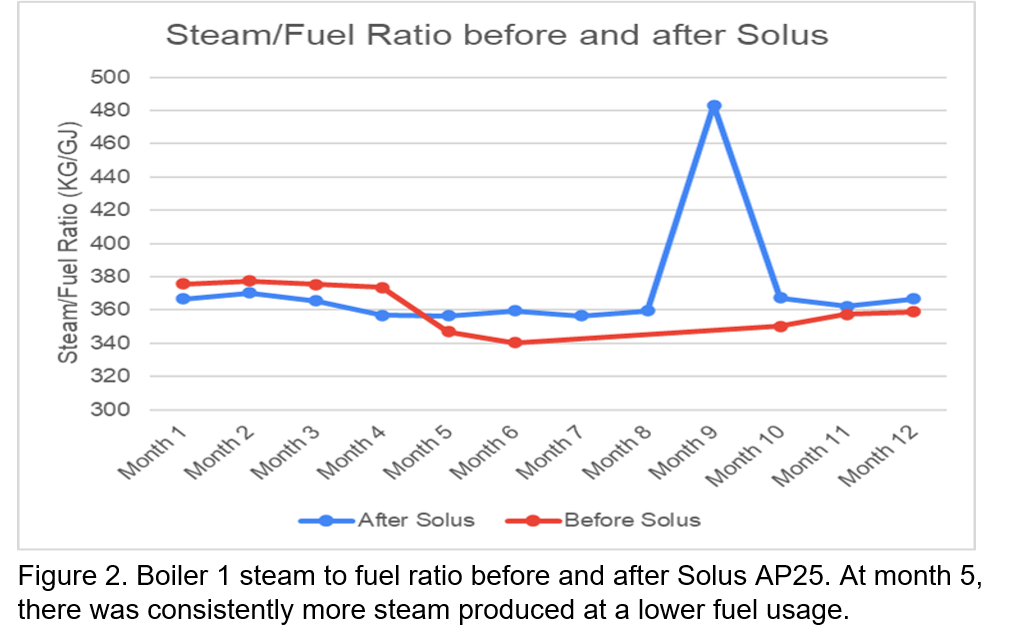

El equipo de Veolia analizó los datos de producción de vapor y consumo de gas natural de los datos operativos de la planta para evaluar la eficiencia de la conversión de vapor en combustible de la caldera que resultó de la eliminación de los depósitos de dureza. Los cálculos compararon la entrada de energía del combustible en relación con la salida de energía del vapor.

Para establecer una comparación de referencia de la mejora de la eficiencia de la caldera, esta evaluación comparó el período posterior a la aplicación de Solus AP25 con el mismo período del año anterior, donde se había realizado el escalado de dureza. Las calderas experimentaron una mejora combinada del 15 % en la eficiencia al cambiar la química del tratamiento interno a Solus AP25 y eliminar los depósitos de dureza.

Esta mejora de la eficiencia se tradujo en un ahorro total de 79,715 dólares canadienses. Además, se evitaron 3,029 toneladas de emisiones de eCO2 en la planta al reducir el consumo de combustible debido a la mejora en la transferencia de calor una vez que se eliminó el depósito aislante.

Desde su puesta en servicio, esta WRF ha sido reconocida por la National Association of Clean Water Agencies (NACWA) con premios al Máximo Rendimiento por su continua excelencia en el tratamiento de aguas residuales.

*Marca registrada de Veolia; es posible que esté registrada en uno o más países.