A global leading talc manufacturer, IMI Fabi, has operations across the Americas, Europe and Asia. In the USA, they have been operating a talc mine and processing facility in Benwood, West Virginia since 2003.

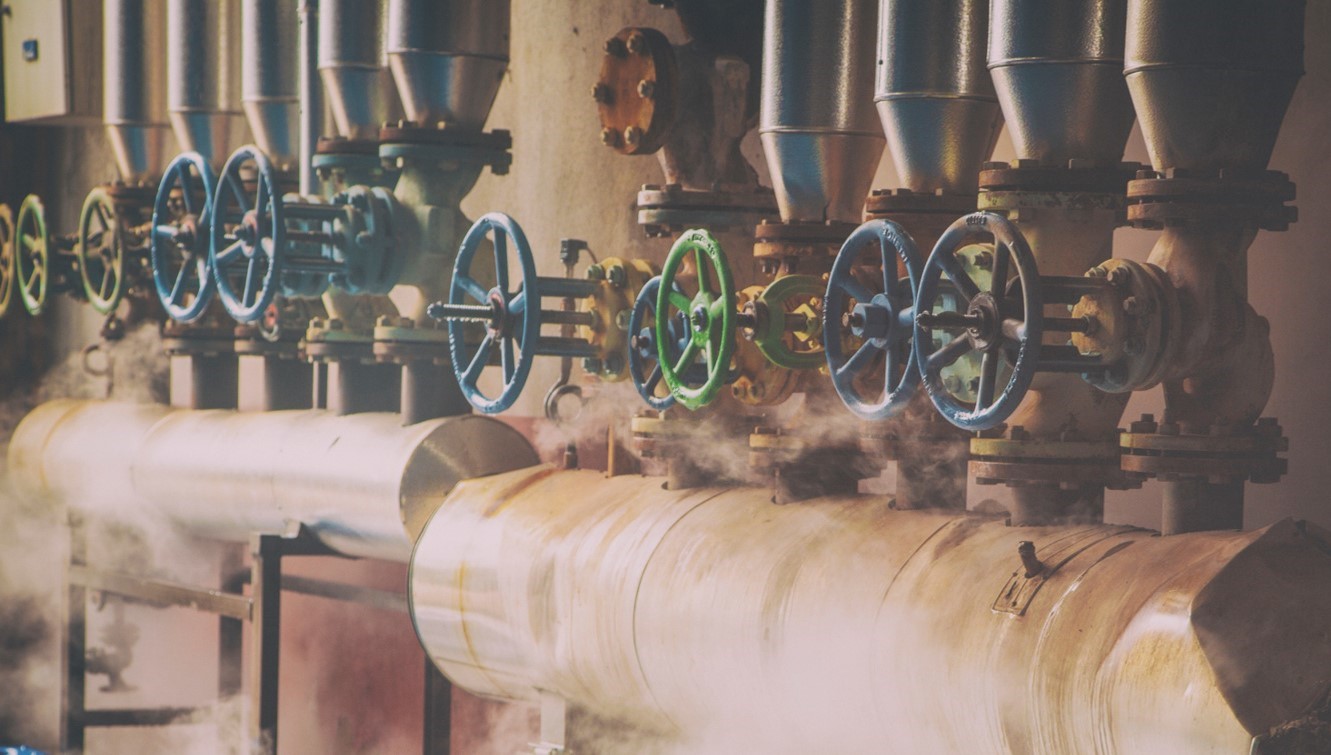

The IMI Fabi Benwood plant operates year-round, but their new cooling tower design enables them to run them in air-cooling (i.e. dry) mode during the winter season. In order to allow for dry operation of the cooling system, the heat exchangers must be exempt from scaling and deposition. Due to the challenging make-up water composition containing high levels of hardness, manganese and alkalinity, the incumbent treatment program had been unable to prevent mineral scale formation in the heat exchangers (Figure 1).

Figure 1: Heavy mineral scale in the heat exchangers when treated with the incumbent competitor’s program would prevent dry-mode operation during the winter months.

With the presence of mineral deposits on the exchangers, the new cooling towers would have to be operated in wet mode instead of dry mode during the winter. This would have represented an additional demand in water and chemical treatment that IMI Fabi wanted to prevent in order to improve their sustainability and cost of operation. A better treatment solution to prevent deposit accumulation was required. .

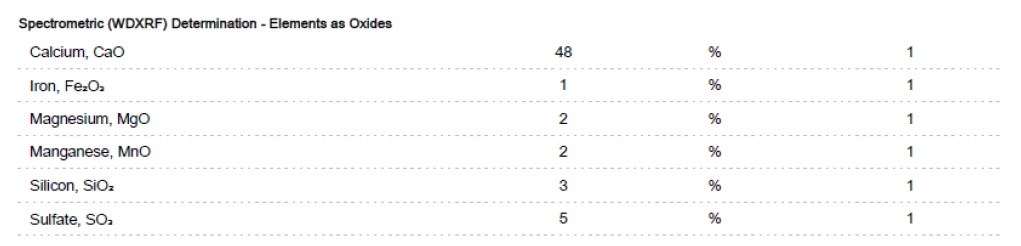

When the plant asked for Veolia to help them develop a solution to allow them to operate the cooling tower in air-cooling mode seasonally, a full system audit was conducted to understand the nature of the deposit, the condition of the system, and assess potential mitigation pathways.

Table 1: Cooling tower deposit analysis demonstrates calcium hardness-based scale reducing heat exchanger performance and preventing dry-mode operation.

The competitor's treatment program was a conventional phosphate-based program for corrosion control, with only limited properties for preventing and dispersing deposits. The Veolia team recommended to upgrade the cooling tower treatment chemistry to the GenGard* program, which contains its advanced STP dispersant technology and AEC calcium carbonate inhibitor. STP is a patented and industry-leading dispersant chemistry that has shown in countless field application its ability to control hardness, alkalinity and phosphate-based deposit from forming in cooling systems. AEC has been the leading calcium carbonate scale inhibitor in the industry for many years, and still proves to be delivering superior results.

Resultado

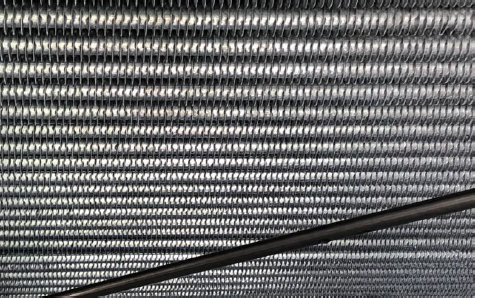

Following the implementation of GenGard chemistry on the new cooling towers at IMI Fabi Benwood no hardness deposit formation was observed, with the heat exchangers remaining much cleaner than when using the competitor’s treatment program (Figure 2).

With the help of the new chemistry, the IMI Fabi Benwood plant was able to keep the cooling system and its heat exchangers free of deposit during operation, which enabled the system to run in dry-mode during the winter without performance issue and preventing significant operating costs.

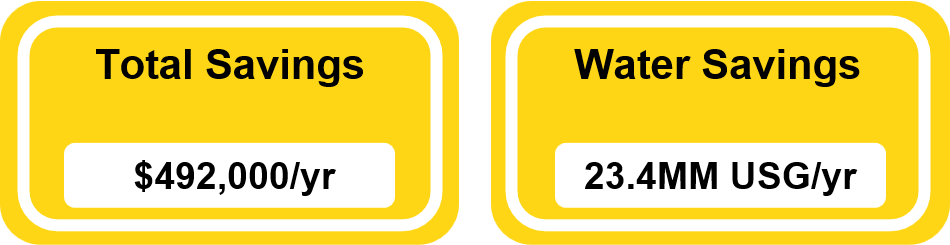

Enabling the cooling tower system to operate in dry-mode every winter saved IMI Fabi approximately $492,000 per year in operation, maintenance and chemical costs. It also reduced annual water consumption by 23.4 MM gallons.

Desde su puesta en servicio, esta WRF ha sido reconocida por la National Association of Clean Water Agencies (NACWA) con premios al Máximo Rendimiento por su continua excelencia en el tratamiento de aguas residuales.

Figure 2: Clean heat exchanger is now free of deposit, following the implementation of GenGard and STP treatment chemistry, can now reliably operate in dry-mode.