Membranas de ultrafiltración presurizada ZeeWeed*

Enabling the world's most advanced water treatment

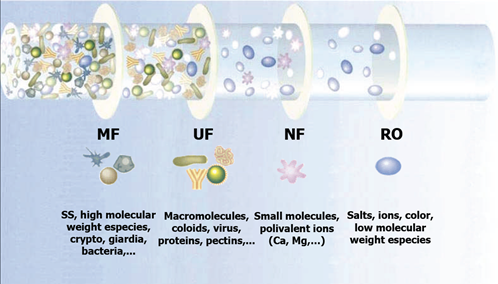

Veolia offers two premium pressurized ultrafiltration (UF) membrane solutions, each engineered for specific applications:

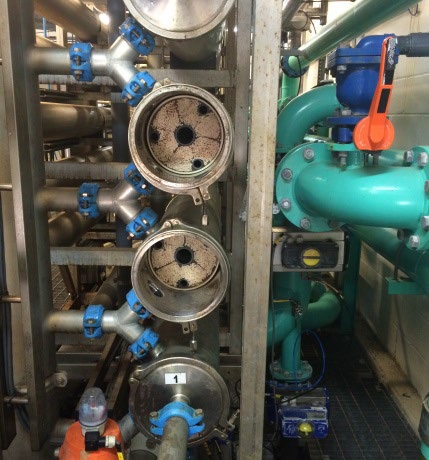

ZeeWeed 1500 UF membranes feature advanced PVDF hollow-fiber design, offering exceptional versatility across applications. From municipal drinking water to industrial processes, its adaptable configuration delivers consistent, high-quality water in diverse operating conditions.

ZeeWeed 700B UF membranes, with Veolia's Sevenbore* inside-out hollow-fiber design, excels in high-throughput operations. This robust design is ideal for reverse osmosis (RO) and nanofiltration (NF) membrane pre-treatment in municipal and oil & gas applications, making it the choice for many of the world's largest treatment facilities..

By providing superior quality water, ZeeWeed pressurized ultrafiltration membranes enables advanced treatment solutions that address the world's most challenging water needs